Vacuum Forming

We can create custom solutions for any design brief. Explore the following portfolio to see examples of our industry leading work and design capabilities.

Vacuum Forming

Vacuum forming is our core business which has been the catalyst to our rapid growth within the plastics industry.

Vacuum Forming

In simple terms, the process of vacuum forming involves a flat sheet of plastic being perimeter clamped and then heated to an elastic forming state.

The mould is then pressed against the sheet, and a vacuum ensures the sheet maintains its place until it has cooled down. Once the sheet has cooled down, the plastic retains the shape of the mould.

Depending on the complexity of the moulding, several different styles of tools can be manufactured to achieve varying results.

The vacuum forming process is extremely cost-effective for small through to large volume projects. With the low costs of prototyping and tooling in comparison to other types of plastic manufacturing, it is often considered a more viable method of production. Advances in tooling materials have meant that some types of tools have a virtually unlimited lifespan. Being a wholly Australian family-owned company and having all the required processes in-house guarantee lower overall production lead times and costs.

Vacmould Display’s manufacturing process caters to a wide range of applications entirely dependent on the client’s requirements. We can mould gauges from 0.38mm up to 12mm in thickness with overall sheet moulding dimensions up to 3500mm x 2500mm with a 1000mm moulding depth. We have a broad range of custom-made vacuum formers, ensuring that we have the right machine to produce the highest quality part in the most cost-efficient manner.

We work with a large number of standard material which is commonly kept in stock, ranging from UV grade acrylic caped for outdoor applications, sanitary grade material for the hospitality and medical industries, standard ABS, Acrylics, HDPE, polypropylene, polycarbonate styrene, and ASA. All material is available in a variety of colours, textures, as well as finishes ranging from chrome, soft-touch, carbon fibre and wood grain laminates to list a few common examples.

We currently produce components for some of Australia’s largest retail and commercial companies. Some of our current vacuum forming projects range from

- Large custom-made heavy-duty pallets

- Complete RV/caravan front and rear fascias

- Internal bathroom basins and full shower cubicles

- Interior fittings and fixtures for emergency service vehicles

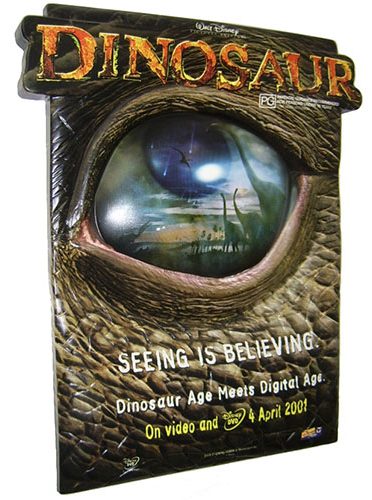

- Colour printed point of sale displays for cosmetic, supermarket and retail consumer markets

Our team of designers and engineers will work closely with you to create a design that is tailored to each individual application. Once a design has been established our team will create rendered 3D drawings for approval. Once the design has been approved we will begin to machine the appropriate tool material using our state-of-the-art 5-axis CNC machines. The first off-production part will be given to the customer to physically inspect the part prior to final approval for full production. We are continuing to improve technologies as they become available in order to eliminate the guesswork out of the production processes giving greater control and flexibility to the client.

There is no project too complex or too large for us to handle. Click on the contact link and leave your details and one of our design and engineering consultants will contact you to begin the obligation-free process.

Learn more about the vacuum forming process here.

Our latest work

Take a look through a selection of vacuum forming examples here.

Get in touch with us today

Get in touch with us today for all your vacuum forming and fabrication projects.

Enquire nowVacuum Moulding

Vacuum moulding is traditionally one of the oldest and most common types of processing plastic materials. It is common to see a variety of vacuum moulded products throughout our daily lives.

.Thermoforming

Thermoforming is a form of moulding that can produce a large range of usable products whilst also being one of the more affordable processes of plastic moulding when it comes to tooling costs and low to medium quantity production runs.

.