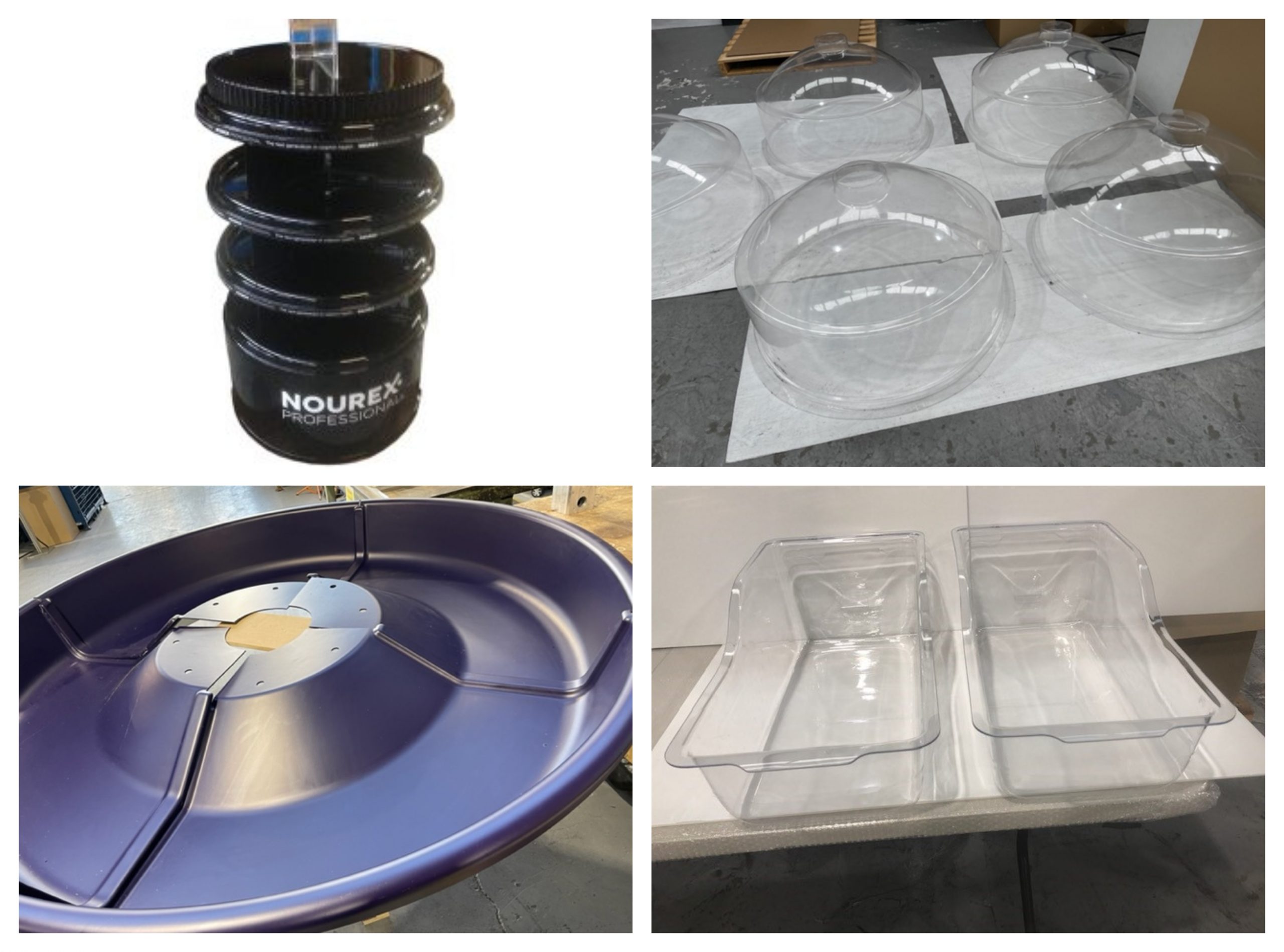

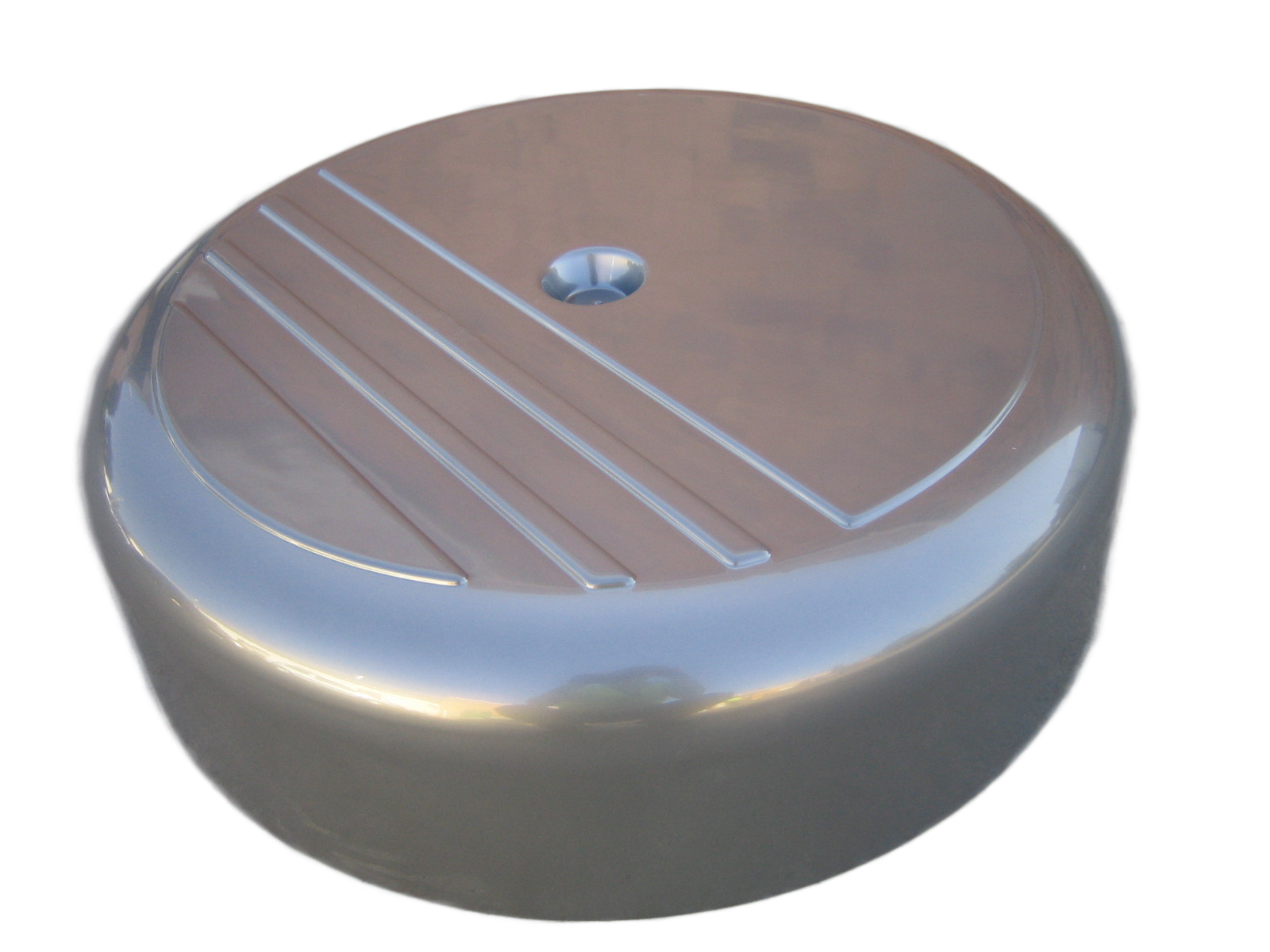

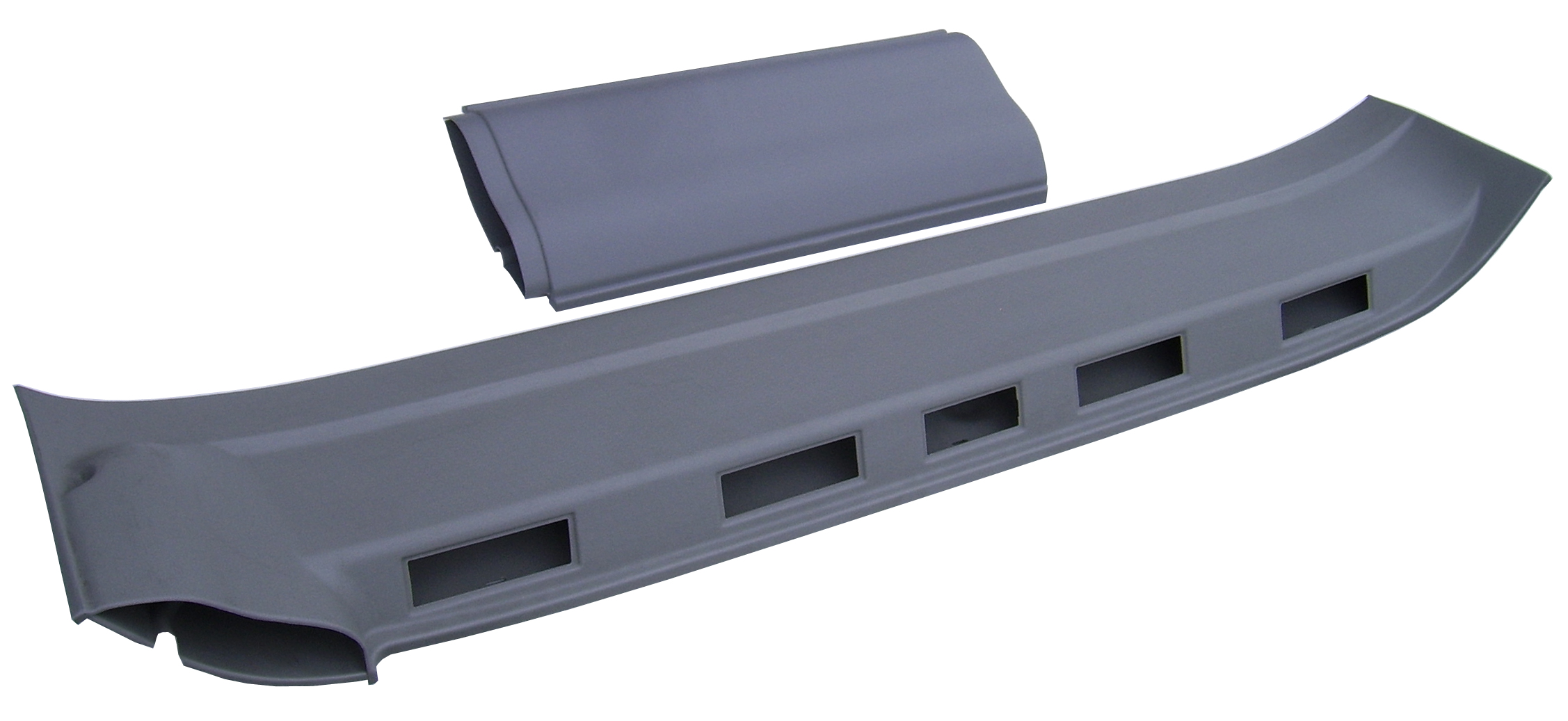

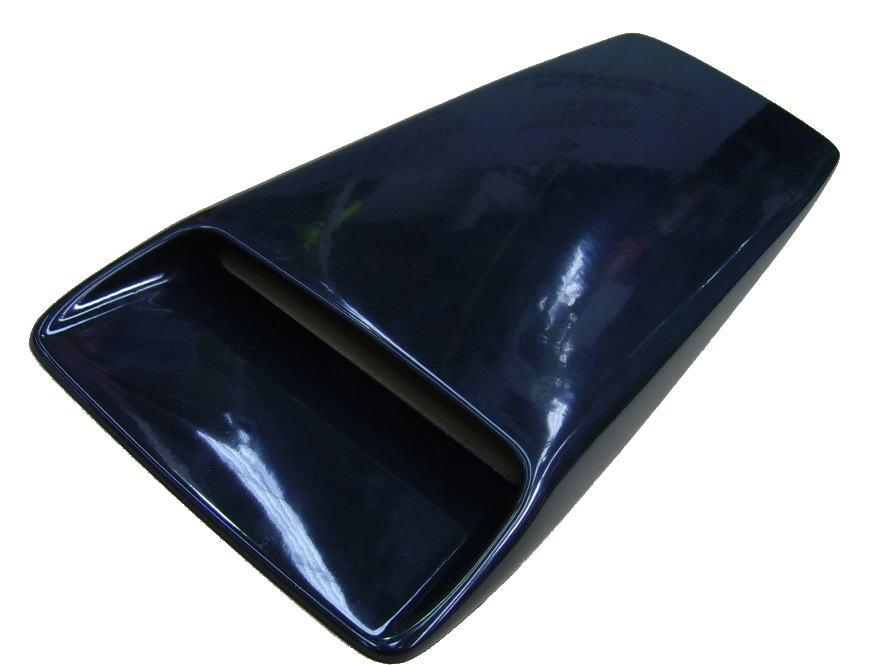

Product Gallery

A small selection of custom manufactured projects. Get in touch with Vacmould Displays for all your vacuum forming and fabrication requirements.

We would like to hear from you

Talk to someone in our design and engineering team to understand how we can help.

Contact us